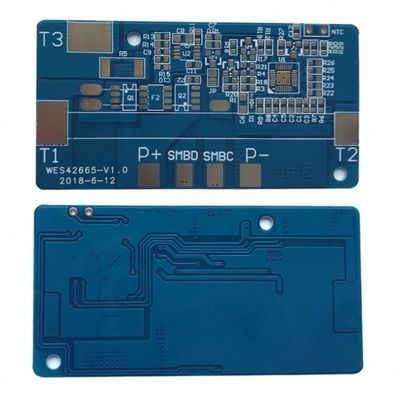

Automotive PCB Blue Soldermask Customized FR4 Circuit Board Immersion Gold

Linked electronics was established in 1998 in Shenzhen, as one of the leading PCB manufacturers in China, is dedicated to provide high-tech PCB products. Our PCB fabrication service includes FR4 PCBs, Aluminum PCBs, HDI PCBs, Multilayer PCBs (up to 32 layers), Gold Finger PCBs and Rogers PCBs manufacturing.

Our service is below:

1)1-32 layers PCB board

2)HDI Blind&Buried via multilayers PCB board

3)High frequency special material base PCB board, like Rogers, Taconic, Arlon, etc.

4)Thick copper Technology, impedance control boards

5)Assembly Processing: SMT, COB, THT

6)Testing Methods: Flying Probe Test, X-ray, ICT and AOI.

Does your company need a high quality finished PCB shipped in

3 Days? 2 Days? Even 24 Hours?

Call us and let's discuss your PCB demand.

Standard Lead time

| Layer Count |

Lead time |

|

| |

S< 1㎡ |

1㎡≤S< 3㎡ |

3㎡≤S< 5㎡ |

5㎡≤S< 10㎡ |

10㎡≤S< 30㎡ |

|

| 2L |

5 |

7 |

9 |

11 |

13 |

|

| 4L |

6 |

8 |

10 |

12 |

14 |

|

| 6L |

7 |

9 |

11 |

14 |

15 |

|

| 8L |

8 |

10 |

12 |

15 |

16 |

|

| 10L |

9 |

12 |

14 |

16 |

17 |

|

| 12L |

10 |

13 |

15 |

17 |

18 |

|

We can provide you with UL approved circuit boards with a variety of final finishes that meet the requirements of RoHS, REACH and Conflict Metals regulations.

Quality Control Process

1. Complete accuracy analysis of customer design (Computer Aided Design)

2. Troubleshooting checklist, Send engineering questions if any.

3. Check plot ( prior approval by customer, if production gerber is requested)

4. Inspection of “First Article Panel” after drilling procedure to ensure IPC-A-600 and customer specifications.

5. Complete Inspection of ALL panels after PTH (Plating Through Holes) to confirm there are no void holes, or any debris.

6. Complete Inspection of ALL panels after film developing to confirm there are no scratches or any under developing.

7. Complete Inspection of ALL panels after film stripping to confirm there are no film chips remaining on panels.

8. After Etching, check to confirm no under/over etching has occurred.

9. Do Cross-Section analysis to confirm quality and proper distribution of copper plating.

10. An AOI (Automated Optical Inspection) is preformed after Tin stripping process, to confirm that there are no shorts or circuitry openings.

11. Complete Inspection of ALL panels after LPI (Liquid Photo Imaging) to ensure that there is no solder mask remaining on the pads.

12. Complete Inspection of ALL panels after finishing process (HASL, Flash Gold, ENIG, or Silver Immersion) to confirm no mask on pads.

13. Complete Inspection of ALL panels after IDENT process to ensure cleanliness of pads before final baking process.

14. Complete Inspection after routing process to ensure customer specifications.

15. Electrical Testing is preformed to ensure integrity of circuit (no shorts or open circuits). QC & A (Quality Control & Assurance).

16. Complete inspection of all finished boards to make sure that all customers’ specifications are met and all IPC-A-600 Standards such as board dimensions, hole and slot sizes, board thickness, and board finish are met.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!