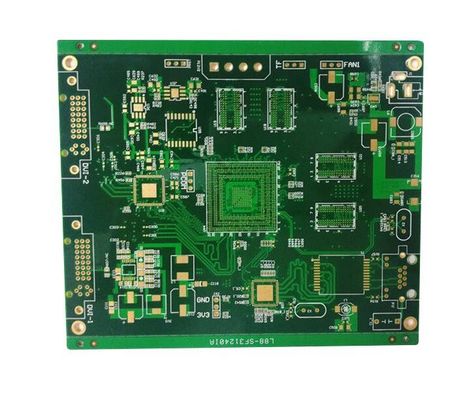

FR4 370HR ENIG Automotive PCB 50ohm Impedance Control LPI Green 1OZ

PCB Manufacturing Capabilties at Linked Electronics

| Layers |

Mass production: 2~32 layers / Proto run: 64 layers |

| Max. Thickness |

Mass production: 394mil (10mm) / Proto run: 17.5mm |

| Material |

FR-4 (Standard FR4, Mid-Tg FR4,Hi-Tg FR4, Lead free assembly material) , Halogen-Free, Ceramic filled , Teflon, Polyimide, BT, PPO, PPE, Hybrid, Partial hybrid, etc. |

| Min. Width/Spacing |

Inner layer: 3mil/3mil (HOZ), Outer layer: 4mil/4mil(1OZ) |

| Max. Copper Thickness |

UL certificated: 6.0 OZ / Proto run: 20OZ |

| Min. Hole Size |

Mechanical drill: 8mil(0.2mm) Laser drill: 3mil(0.075mm) |

| Max. Panel Size |

1150mm × 560mm |

| Aspect Ratio |

12:1 |

| Surface Finish |

HASL,Immersion Gold, Immersion Tin, OSP, ENIG + OSP, Immersion Silver, ENEPIG, Gold Finger |

| Special Process |

Buried Hole, Blind Hole, Embedded Resistance, Embedded Capacity, Hybrid, Partial hybrid, Partial high density, Back drilling, and Resistance control. |

Linked Electronics Co., Limited is one of the well-established China PCB manufacturer with more than 2 decades of experience in producing one-sided, double-sided and multilayer PCB boards. Besides, ceramic PCB, aluminum PCB, and rigid Flex PCB is within our capabilities

Printed circuit boards from our production have a wide application which most are used in electronic instrumentation, aerospace, medical, telecommunications, mining, and transportation industries as well as a multitude of common consumer electronic devices.

Linked Electronics has the capabilities to manufacture variety of printed circuit board you may need for your automotive applications. Our PCBs are TS16949 certified and UL certified, the performance of the PCBs that produced by Linked Electronics is reliable and durable. Reach Linked Electronics, the PCB manufacture in China today for free and no-obligation automotive PCB quote.

PCB Applications on Automotive Industries

Just a few decades ago, it would be difficult to find any cars with any computer technology in it. With the development of car innovations, sophisticated technology appears more on the cars. More and more computerized systems began to sneak in, whether for core system functionality, generating service alerts, enabling safety features or auto driving. Today, no new car can run without an onboard computer — and those computers need a printed circuit boards. In the last 5 years, the auto PCBs demand is 20% more.

Types of Automotive PCBs

Flex PCBs

These boards are made of flexible plastic substrates. They are composed of polyamide or transparent polyester films. These boards can be twisted and bent. Find their applications around bends and corners where it is required in a car.

Rigid PCBs

The rigid boards are made of FR4. These boards aren’t flexible and cannot bend. They are usually found in display monitors and reverse cam screens.

Rigid-Flex PCBs

These are circuit boards are a combination of Rigid and Flexible boards, which are flexible and light in weight. They are implemented in lighting systems.

LED PCBs

The LED boards made of aluminum core substrate because of heat dissipation. They can be found in car indicators, headlights, and brake lights.

HDI PCBs

These boards feature higher wire density per unit area, finer lines and spaces, and high pad connection density. The HDI boards accommodate more components and play a prominent role in miniaturization. These boards are widely used for infotainment systems.

PCB Services that Linked Electronic Provides

1.PCB production of a wide range of Electronic PRINTED CIRCUIT BOARDS even for HIGH-END APPLICATIONS

2.PCB PROTOTYPING – production quantity from one unit in – EXPRESS TIMES

SMALL, MEDIUM, AND LARGE PCB PRODUCTION RUNS or arrangement of production using special technologies.

3.PCB ASSEMBLY with components as well as final functionality testing.

4. LASER CUT STENCILS with various specifications.

5. QUALITY GUARANTEE – 100% TESTING AND INSPECTION before shipping– testing and parameter measuring of printed circuit boards produced, including assembled boards (cross sectional examination of boards with components), utilizing non-destructive methods (electrical measurements or X-ray inspections) as well as destructive methods for bare PCB Board (metallographic cross-sectioning, thermal stress testing, solderability testing, and so on).

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!