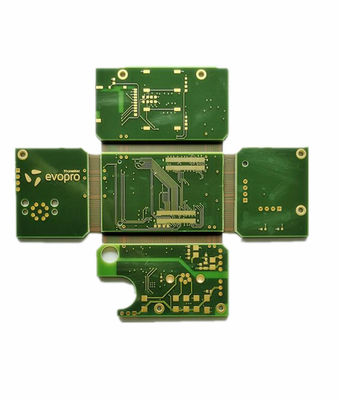

Semi Flex PCB Mutilayer Depth Milled 4 Layer FR4 HASL 1OZ 0.25mm for Flex Area

Thank you for stopping at Linked Electronics, we are a PCB manufacturing in China, specializing in quick turn, high precision and multilayer PCB Board fabrication.

Semi Flex PCB

Unlike the rigid flex PCB, semi-flex PCB is made purely from FR4 material, and on the specific area which requires bending. And the bending section has been thinned to a specific thickness by depth-milled technology so that the area will provides a flexible section of the traditional FR4 PCB. However, semi-flex PCBs have a very limited numbers of bends compared with rigid flex PCBs.

Linked Electronics has been manufacturing and supplying semi flex electronics PCB boards for more than 5 years. Due to our high quality and reliability product performance, our PCBs are widely used in IoT, automotive and industry control products.

Semi Flex PCBs are used most in applications with no dynamic stress of the bending areas. It is relatively much more cost effective than rigid flex PCB boards. It can replace rigid flex PCB board in some applications.

At Linked Electronics, our production have adopted a better solution for semi flex PCB board manufacturing even though it needs more operations process thus it will cost more to build the semi flex PCB boards. Contact us today, let's discuss your semi flex PCB request.

PCB Product Detail

|

Product Name

|

4 Layer Semi Flex PCB |

|

PCB Spec

|

1.6mm with 0.25mm flex area, 1oz, green soldermask, white legend, immersion Gold

|

|

Lead Time

|

10 days |

|

Manfuacturing Standard

|

IPC Class 2, IPC Class 3 standard |

|

Test Method

|

AOI, Flying Probe Test |

Advantages of Semi Flex FR4 PCB

1.Elimination of components

2.More cost effective than rigid flex PCB board

3. Space saving for the final products

FAQs

Q: What PCB service does Linked Electronics provides?

A: We provide one stop PCB service including PCB fabrication, SMT, components sourcing and stencil

Q: What is your minimum order quantity (MOQ)?

A: At Linked Electronics, we have no MOQ. Even 1 pcs is ok for us.

Q: What is needed for PCB & PCBA quotation?

A: For PCB: Quantity, Gerber file and technic requirements (material,size, surface finish treatment, copper thickness,board thickness).

For PCBA: PCB information, BOM,Testing documents.

Q: What are the main applications of your PCB/PCBA services?

A: Automotive, Medical, Industry Control,IOT,Smart Home,Military.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!