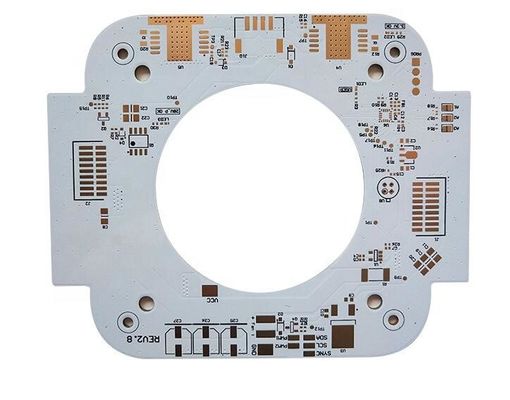

Aluminum PCB is one kind of Metal core PCB, which consists of three layers, copper layer, insulation layer and aluminum core material. It has its unique advantage, maintains a high heat emission efficiency, which is widely used in LED industry.

Classification of Aluminum PCB

1. 1000 series, there are 1050, 1060, 1070 material which is almost100% pure aluminum material. The price is most cost effective of all PCB materials. What used mostly of 1000 series material is 1050 and 1060 at Linked Electronics. The aluminum content is more than 99.5%.

2.5000 series, 5052, 5005, 5083 materials, which is now widely used in aviation, buildings and transport and automotive industries. 5000 series material is alloy of aluminum and 3~5% magnesium. It has very high strength and lower in weight.

3. 6000 series, 6061 is the most typical material. 6000 series are alloyed with magnesium and silicon. They are easy to machine, are weldable, and can be precipitation hardened, but not to the high strengths that 2000 and 7000 can reach. 6061 alloy is one of the most commonly used general-purpose aluminium alloys.

Storage

Aluminum PCB generally store in a dark and dry condition. Most Aluminum PCB will easily get damp, turn black or yellow. After the vacuum package is open, it should be assembly in 24 hours.

Surface Treatment of Aluminum PCB

Generally, all surface treatment could be applied to aluminum boards, HASL lead free aluminum PCB, OSP Aluminum PCB, immersion gold PCB, and immersion silver PCB. Considering the cost, OSP is surface treatment for aluminum printed circuit board that most customer choose at Linked Electronics.

Contact Linked Electronics, one of the leading PCB and PCBA service supplier today, and let's discuss about your Aluminum PCB demand.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!